Tile installation looks simple from the outside, but anyone working in construction or home renovation knows it depends heavily on the tools behind it. This is why many buyers, distributors, and contractors look for a dependable Tiling Tools Factory that understands real job-site needs and product consistency.

A well-run Tiling Tools Factory usually covers a wide range of products used throughout different stages of tile work. These often include tile cutters, spacers, tile leveling systems, trowels, mixers, and finishing tools. While the categories seem basic, the difference in durability and ease of use becomes obvious once they are tested on-site.

Factories that focus on consistent sizing, clean cuts, and strong material choices can help installers avoid rework and delays. When you're sourcing tools in bulk, these differences translate directly into smoother workflows and fewer quality issues.

One factor many buyers overlook is the material process behind each tool. A dependable Tiling Tools Factory generally uses steel with stable hardness, reinforced plastics, and well-balanced metals for cutters and trowels.

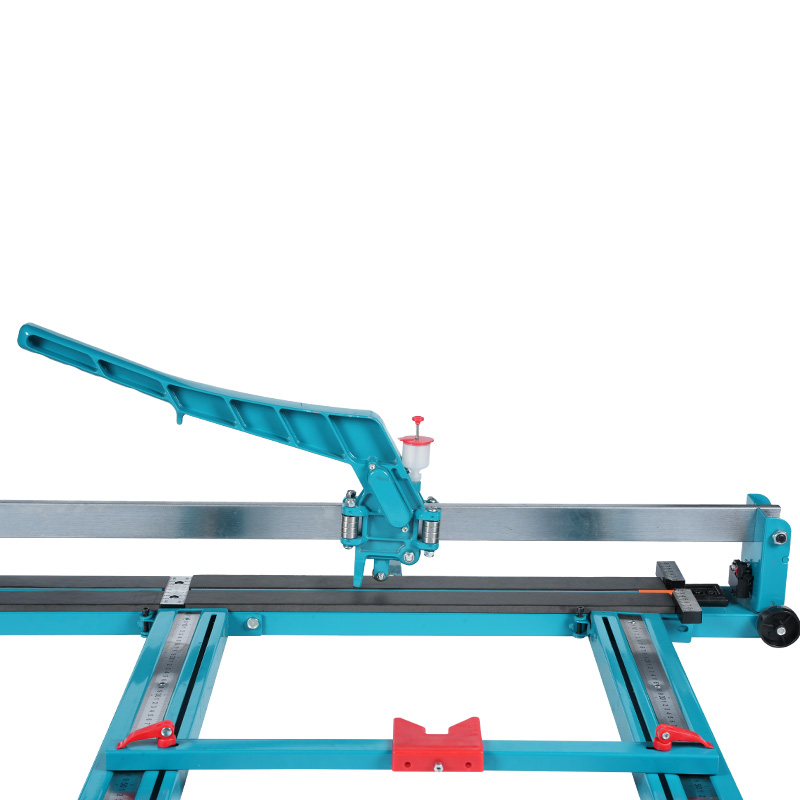

Tile cutters need steady rails and blades that stay sharp through repeated use.

Tile spacers and wedges must keep their shape without softening or deforming.

Trowels require comfortable grips and strong bonding between handle and blade.

When the materials are consistent, installers spend less time adjusting or replacing tools in the middle of a project.

For distributors and wholesalers, the value of consistent production is even more important than one-off quality. A reliable Tiling Tools Factory builds its workflow around stable molds, clear QC steps, and packaging that protects products during transport.

Buyers should pay attention to:

These small details reflect how much control the factory keeps over its production line.

With competition growing across e-commerce and retail channels, private-label customization can be a big advantage. Many clients look for a Tiling Tools Factory that accepts logo printing, color variations, personalized packaging, or adjustments to tool size.

Some factories also offer R&D support — small improvements like changing grip textures, altering blade thickness, or redesigning leveling tools can help your products stand out in both professional and DIY markets. This flexibility often becomes a deciding factor for long-term cooperation.

Beyond production, communication and delivery speed also reflect how mature a factory is. A helpful Tiling Tools Factory usually provides:

It's not just about selling tools — it's about building a workflow that reduces uncertainty for clients and helps them serve their own customers smoothly.

Choosing the right Tiling Tools Factory isn't only about price. It's about steady product quality, practical tool design, and dependable service. When a factory understands what installers deal with every day, its tools tend to perform better onsite, making tile installation easier, cleaner, and more efficient. For businesses looking to build a stable supply chain, finding a factory that can support long-term cooperation brings real value.

English

English русский

русский Español

Español italiano

italiano